August![]() /

/![]() September

2009

September

2009

A Basement Is Born

With the outer basement

walls complete, and the shuttering removed, the block workers came in to build

the internal walls.

The insulated cavity is 300mm wide – three times the width of the cavity

in a conventional house. The uninsulated section,

nearest the camera, will be a storage area below the conservatory.

It was intriguing to

see these walls being formed, as they will actually be the inside of our finished

basement.

Along the top is a row of special load-bearing insulated blocks, which will

prevent heat from the ground floor slab

above being conducted down into the basement walls.

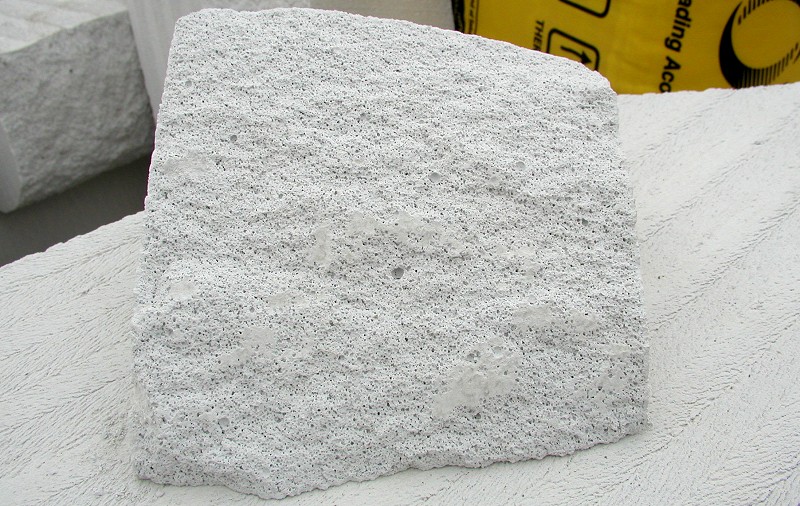

On closer inspection

it's easy to see the multitude of air bubbles which give these blocks

their insulating properties. Like a brick Aero bar, in a way.

Once the internal work

had been completed, back-filling began around the basement,

which slowly began to disappear into the ground.

For environmental reasons

we used crushed demolition waste instead of the usual freshly quarried aggregate.

This provides drainage, preventing pools of water forming outside the basement

walls. The white polystyrene layer

protects the waterproofing material from the jagged edges of the rubble.

Now was the time to

begin installing the 'ground tube' for the ventilation system. Fresh air is

drawn into the house through

this tube, buried 3 metres underground where the temperature is relatively

constant all year round. This means the air

is warmed in winter, and cooled in summer, helping to keep the internal temperature

stable, but with no energy use at all.

On site to see their system being installed were Steve Richmond from Rehau

UK, and visiting from Rehau USA, John Kimball.

Andrew and Sean from

the groundworks team prepare the laser levelling device which helps them to

install the

ground tube at the correct gradient.....

.......by aligning the

beam with a sight placed at the far end of each length of pipe.

The trench is then carefully

back-filled, one section at a time.

Honorary site manager

Max, now fully health and safety compliant in his smart new high-visibility

jacket,

checks the quality of the work.....

.....and issues instructions

to an incredulous Sean.

Following the ground

tube installation, back-filling continued, almost up to the final ground level.

Here's the basement, now very much in the ground, with construction underway

on the structure which will support

the massive reinforced concrete ground floor slab, to be poured in-situ. More

on this in the next update....